Excellent supplier of high-precision parts in China

- 8000+㎡ production scale

- 100+ technical engineers

- 100+ high-precision equipment

- 10000+ product cases, ±0.005mm processing accuracy

Excellent supplier of high-precision parts in China

- 8000+㎡ production scale

- 100+ technical engineers

- 100+ high-precision equipment

- 10000+ product cases, ±0.005mm processing accuracy

Agile Manufacturing

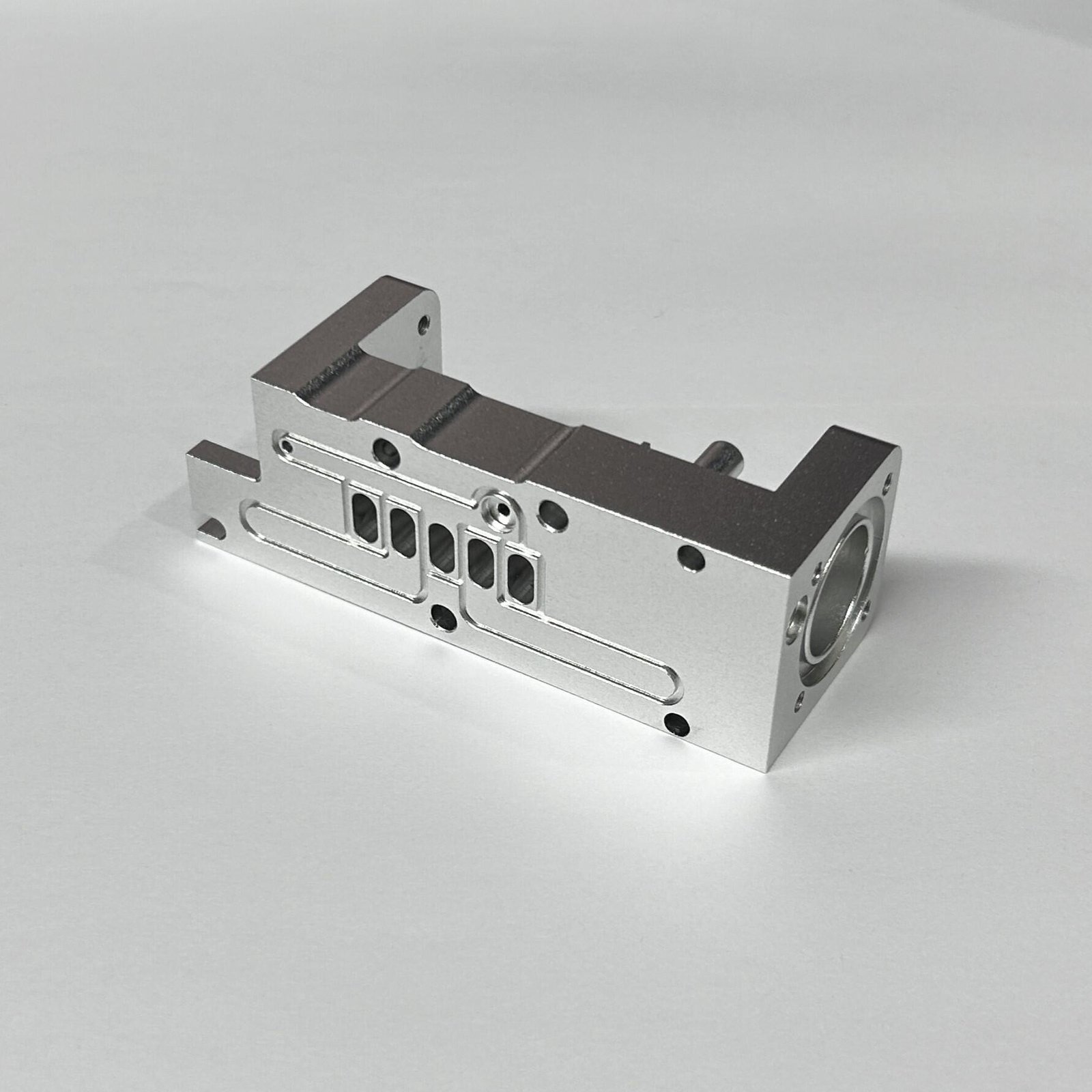

Five-axis non-standard parts custom processing, various precision and complex parts production and processing

Precision machining experience Flexible customization to meet diverse needs

From communication to order confirmation, product production and processing and after-sales have exclusive engineers and you docking!

Quotation and processing flow

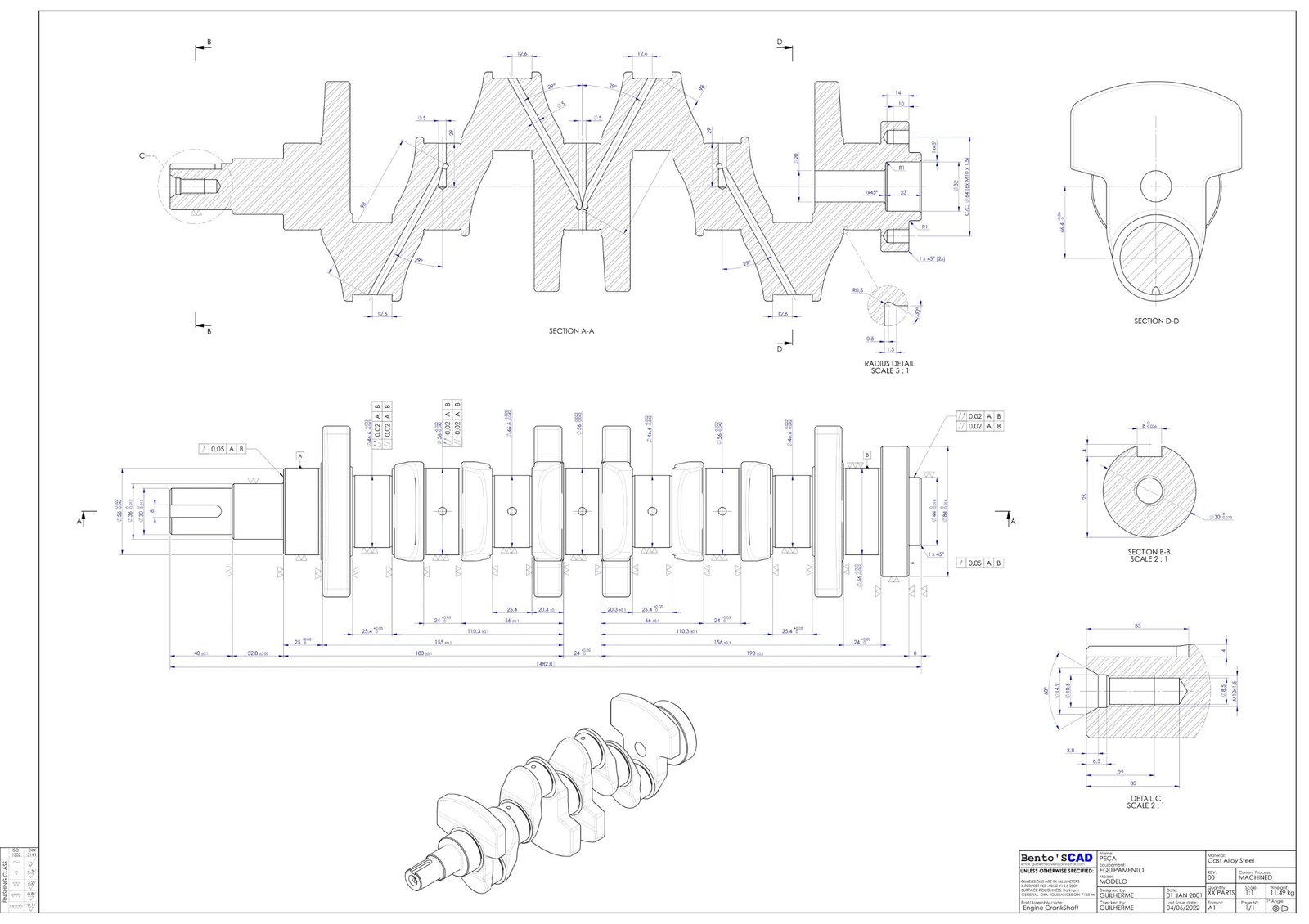

Image review

Provide 2D or 3D drawings of the product. Our company will evaluate it as soon as possible after receiving it and confirm the required materials, surface treatment requirements and quantity according to the drawing requirements.

Evaluation and quotation

Our professional engineers will evaluate the product, determine the process and difficulty, and give a professional quotation.

Signing a contract

After the contract is drafted, both parties need to carefully review the contract terms to ensure that the contract content is accurate and in line with the wishes of both parties.

Product Delivery

The finished products are fully inspected to ensure the quality of the products. Appropriate packaging materials and methods are selected to prevent the products from being damaged by bumps, scratches, corrosion, etc. during transportation. The transportation methods can be air or sea.

Agile manufacturing focuses on precision parts processing and production

Agile Intelligent Manufacturing Technology (Shenzhen) Co., Ltd. is a manufacturing company specializing in the processing of various precision parts. Its main application areas include: optical instruments, communications 5G, semiconductor equipment, medical equipment, motorcycles, automobiles, drones, manipulators, robots, aerospace, military and other core precision parts.

Fully Customizable

CNC machining is your best choice

- Process classification: milling, turning, drilling, laser cutting, EDM, etc

- Material classification: aluminum alloy, stainless steel, copper and other metal materials, as well as some engineering plastics

- Clarify technical details: determine the technical parameters of the parts, including shape, size, tolerance range, surface roughness, etc

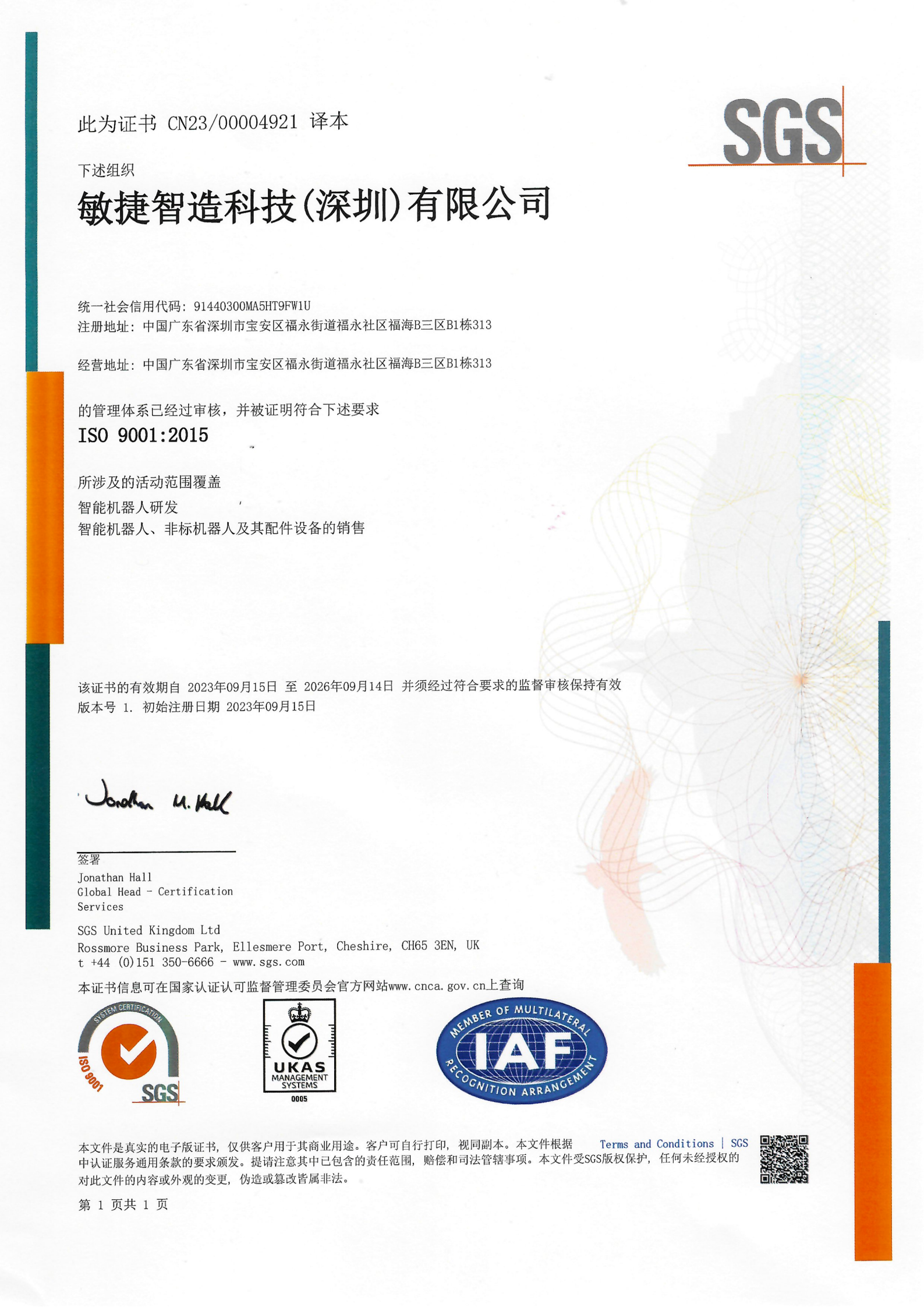

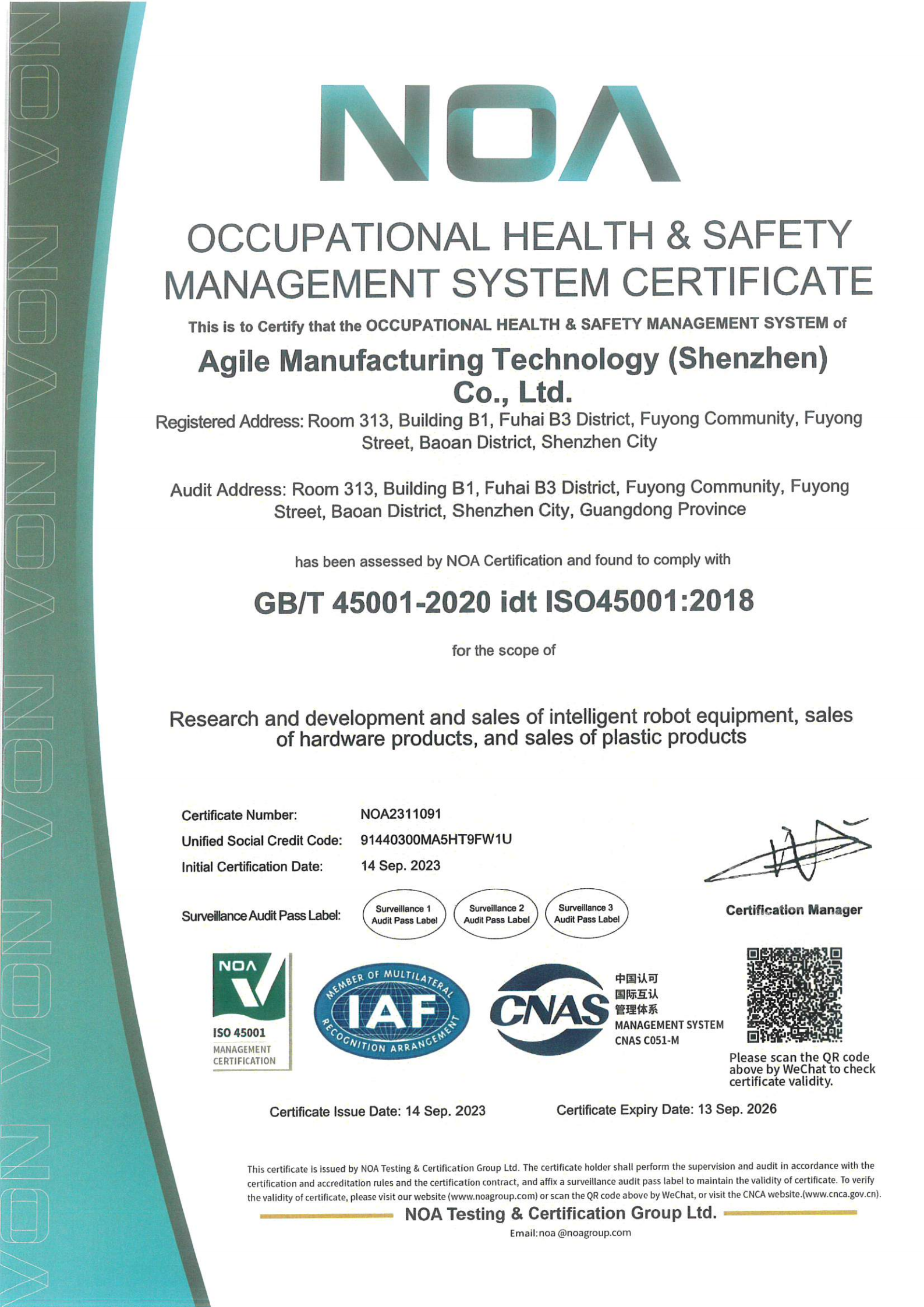

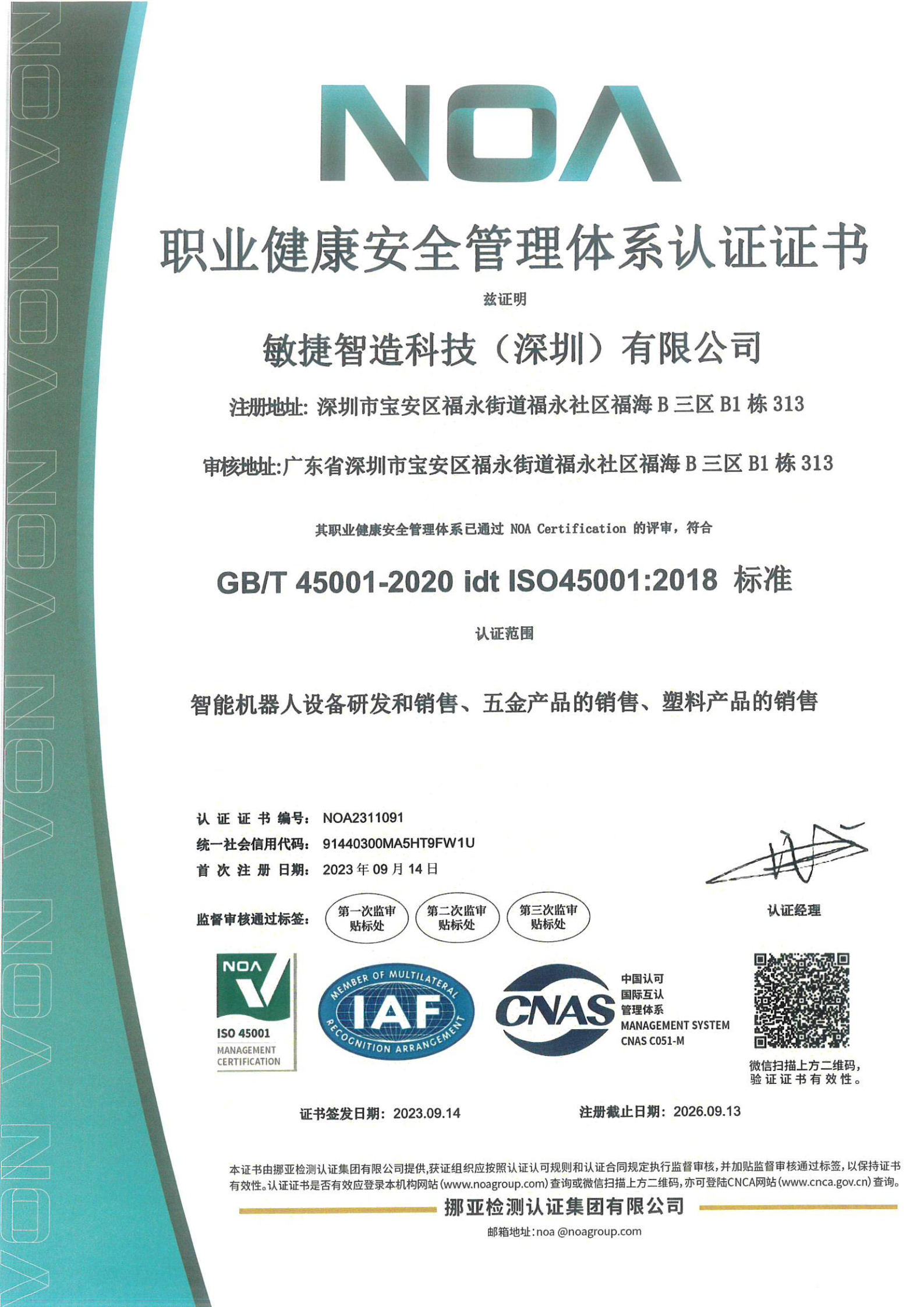

Authoritative certification quality assurance

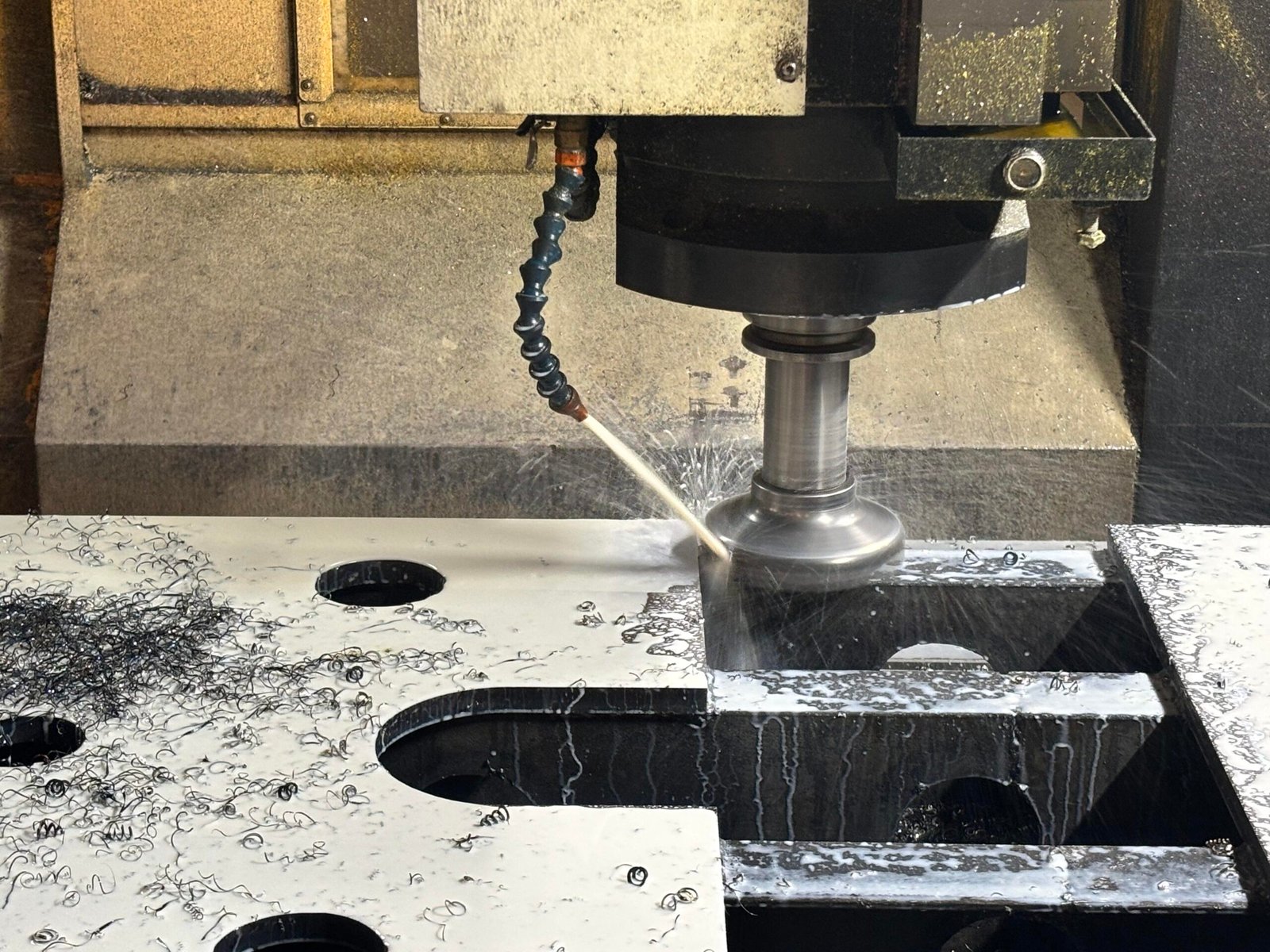

Production Equipment

The production equipment includes Japanese Mazak five-axis, four-axis, and three-axis CNC machining centers, Taiwan imported CNC lathes, grinders, milling machines, drilling machines, wire cutting and other high-precision production equipment.

The testing equipment includes Hexagon three-coordinate testing instruments, projectors, altimeters, film thickness testers, hardness testers, roughness testers, HRC hardness testers and other high-precision testing equipment.

Japanese Mazak CNC machine tools

American Haas CNC machine tools

Taiwan Yongjin Machine Tool

Hexagon coordinate measuring machine

Measuring equipment

Caliper

About Agile Manufacturing

Agile Manufacturing is a professional company focusing on precision parts processing, five-axis linkage parts processing, complex parts processing, Invar parts processing, titanium alloy parts processing, engineering plastic parts processing and non-standard parts processing. It provides customers with one-stop modular assembly services and focuses on the fields of medical, aviation, energy, automobile, communication, etc. It has accumulated many years of rich experience in precision processing, surface treatment and other technical processes of difficult-to-process metal materials such as Invar alloy and titanium alloy.

Agile Manufacturing has a first-class management and technical team, high-end production equipment, precision testing instruments, a complete ISO management system, and our spirit of continuous progress and excellence in craftsmanship, allowing us to provide customers with “the highest quality products and the best quality services.”

We look forward to winning your trust and support with our sincere service!

Standard, performance, high-quality CNC processing manufacturers

Our company has more than 20 years of industry experience, which enables us to quickly understand your needs and develop a procurement plan that best suits you.

CNC machining: the perfect fusion of technology and craftsmanship

Unique creativity is no longer limited to drawings, but is presented in three-dimensional and real form

Common Questions

Most Popular Questions.

We have listed some questions you may ask. If you have more inquiries about our products, you can send an inquiry to contact us.

Stainless steel machining refers to the process of cutting, milling, drilling, grinding, stamping, bending and other processing of stainless steel materials through mechanical equipment to obtain parts or products with the required shape, size and precision. Then, the following editor will introduce in detail the process flow of stainless steel machining, which generally includes the following steps:

Material preparation: Select suitable stainless steel materials according to processing requirements, and perform pre-processing such as cutting and deburring.

Programming design: Use CAD/CAM software to perform 3D modeling and programming of the processed parts, and generate processing paths and tool paths.

Fixture installation: Install the pre-processed stainless steel materials on the machine tool and fix them with fixtures.

Machine tool processing: Start the machine tool and perform processing according to the programmed processing paths and tool paths, including cutting, milling, drilling, grinding and other processes.

Quality inspection: Perform size, shape, accuracy and other aspects of the processed parts to ensure that they meet the design requirements.

Subsequent processing: Clean, deburr, rust-proof and other subsequent processing of qualified parts for assembly or use.

Five-axis machining (5 Axis Machining) is an advanced mode of CNC machine tool processing. It has significant advantages in the field of mechanical manufacturing, especially when processing parts with complex geometric shapes. Its working principle and usage are as follows:

1. Working Principle

Five-axis machining is based on a three-dimensional coordinate system. It achieves precise machining of workpieces by controlling the movement of axes in different directions on the machine tool (three linear moving axes of x, y, and z plus any two rotating axes of A, B, and C). The movement of these coordinate axes can be achieved by the movement of the worktable or the tool, but the direction is defined by the movement direction of the tool relative to the workpiece.

Generally, five-axis linkage refers to the linear interpolation motion of any five coordinates of x, y, z, A, B, and C. This multi-axis linkage control system can process the workpiece in multiple directions at the same time, thereby achieving high-precision processing of parts with complex geometric shapes.

2. Applications

Due to its unique advantages, five-axis machining has a wide range of applications in many fields, mainly including:

·Aerospace: In the field of aerospace, five-axis machining is often used to process body parts, turbine parts and impellers with free-form surfaces. These parts have complex shapes and high precision requirements. Traditional machining methods are difficult to meet the requirements, while five-axis machining can easily cope with them.

·Automobile manufacturing: In automobile manufacturing, five-axis machining is used to manufacture parts with complex shapes such as engine cylinders and gearbox housings. These parts are crucial to the performance and reliability of automobiles, and the high precision and high efficiency of five-axis machining can meet the needs of the automobile manufacturing industry.

·Mold manufacturing: The mold manufacturing industry has high requirements for machining accuracy and surface quality. Five-axis machining can achieve high-precision machining of mold cavities and cores, and improve the manufacturing accuracy and service life of molds.

·Precision machinery: In the field of precision machinery, five-axis machining is used to manufacture complex parts of precision instruments, medical equipment, etc. These parts are usually characterized by high precision and high complexity, and five-axis machining can meet their machining needs.

Other fields: In addition, five-axis machining is also widely used in industries such as compressor processing, medical, robotics, defense, shipbuilding and alternative energy. In these industries, five-axis machining can handle complex parts such as various curved geometries, narrow cavities, overhanging features, etc. that are difficult to cover with other processing methods, thereby improving production efficiency and product quality.

Aviation CNC machining, or computer numerical control precision machining, is a technology that uses computer-controlled machine tools to process aviation parts. It uses CAD software to draw part drawings and import the data into the control system of the CNC machine tool. The control system performs digital quantification processing, and then controls the motion trajectory of the machine tool through the computer to achieve precise processing purposes.

1. Aircraft engine parts: Aircraft engines are one of the core components of aircraft, and the processing accuracy and performance of their parts directly affect the performance and safety of the entire aircraft. Precision CNC processing technology can achieve high-precision processing of engine parts, such as blades, bearings and other key components.

2. Fuselage structural parts: Fuselage structural parts are the skeleton of the aircraft and bear various complex loads. CNC processing technology can ensure that the size and shape of these structural parts meet the design requirements to ensure the overall stability and safety of the aircraft.

3. Avionics equipment parts: With the continuous development of avionics technology, avionics equipment is more and more widely used in aircraft. Precision CNC processing technology can achieve high-precision processing of avionics equipment parts, such as circuit boards, connectors and other components, to ensure their accuracy and reliability.

With the continuous advancement of science and technology, the mechanical parts processing industry is also developing continuously. The precision control of mechanical parts processing is the key link to ensure that the parts meet the design requirements. The following are several main methods to control the precision of mechanical parts processing: projects.

1. Tolerance matching

Definition: By setting a reasonable tolerance range, ensure that the parts can cooperate with each other during assembly to achieve the expected accuracy requirements.

Function: Tolerance matching is an important means to control the dimensional accuracy of parts. It allows the size of parts to fluctuate within a certain range, but still ensures the overall accuracy after assembly.

2. Form and position tolerance control

Definition: Form and position tolerances include parallelism, verticality, coaxiality, etc. The accuracy of the product can be improved by accurately controlling these form and position tolerances.

Method: Use high-precision measuring tools and methods to accurately measure and adjust the form and position tolerances of parts to ensure that the shape and position accuracy of the parts meet the design requirements.

3. Surface roughness control

Definition: The roughness of the surface of the part has a great influence on the accuracy.

Method: By selecting appropriate processing methods and parameters, such as cutting speed, feed rate, cutting depth, etc., to control the surface roughness, thereby improving the accuracy. In addition, subsequent processing processes such as grinding and polishing can also be used to further reduce the surface roughness.

4. Use high-precision processing equipment

Importance: Using high-precision machine tools and cutting tools is the key to ensuring processing accuracy.

Equipment: Such as CNC lathes, CNC milling machines, grinders and other high-precision processing equipment, which can achieve high-precision cutting and processing, thereby improving the accuracy of parts.

5. Process control

Definition: Reasonable arrangement of the processing process sequence to avoid deformation and error accumulation during the processing process is also an important means to improve accuracy.

Method: Ensure the stability and improvement of processing accuracy by optimizing the process flow, selecting appropriate processing methods and parameters, and controlling factors such as temperature and vibration during the processing.

6. Measurement and inspection

Importance: Using precision measuring tools to measure and inspect parts during and after processing is a key step to ensure that parts meet the accuracy requirements.

Tools: Commonly used measuring tools include micrometers, vernier calipers, microscopes, three-coordinate measuring machines, etc.

7. Temperature control

Influence: During the processing process, changes in temperature will affect the performance and size of the material, thereby affecting the processing accuracy.

Method: Reduce the impact of temperature on processing accuracy by controlling the temperature of the processing environment and using coolants.

8. Special methods and techniques

Trial cutting method: obtain the specified dimensional accuracy through the repeated process of “trial cutting-measurement-adjustment-re-trial cutting”, which is suitable for single-piece production.

Adjustment method: first adjust the relative position of the tool and the workpiece on the machine tool, and keep it unchanged during the processing of a batch of parts, which is suitable for batch and mass production.

Automatic control method: a series of work such as measurement, compensation, adjustment and cutting in the processing process is automatically completed, such as CNC machine tool processing or machining center processing, with stable quality and high productivity.

The problem of uneven surface of mold parts may be caused by many factors, including mold design, processing process, material quality and operating specifications. To solve this problem, the following solutions can be adopted:

1. Optimize mold design

Reasonably design the mold structure: Ensure that the mold structure is designed reasonably to avoid stress concentration during stamping or forming, thereby reducing the surface unevenness.

Improve processing accuracy: Perform high-precision processing on the parts of the mold to ensure the matching accuracy between the parts to reduce the surface unevenness caused by improper matching.

2. Improve the processing process

Control processing parameters: During the processing, strictly control parameters such as cutting speed, feed rate, cutting depth, etc. to ensure the stability and consistency of the processing process.

Use appropriate cutting tools and tools: Select cutting tools and tools with good quality and strong applicability to reduce vibration and wear during the processing process and improve the flatness of the processed surface.

3. Select high-quality materials

Material selection: Ensure that the selected mold materials have stable quality, uniform composition, no impurities and internal defects. High-quality materials can improve the hardness and wear resistance of the mold and reduce the surface unevenness.

Heat treatment process: Appropriate heat treatment of mold materials, such as quenching and tempering, to improve the hardness and toughness of the material, improve the internal structure of the material, and thus reduce the problem of surface unevenness.

4. Strengthen operating specifications

Professional training: Provide professional training for operators to improve their skill level and awareness of operating specifications. Ensure that operators can strictly follow the operating procedures during the processing process to avoid surface unevenness caused by improper operation.

Regular maintenance: Regularly maintain and care for the mold, such as cleaning the dust and iron filings on the mold surface, checking the wear of the mold, etc. Timely discovery and resolution of problems can reduce the occurrence of surface unevenness.

5. Improve environmental conditions

Keep the environment clean: Ensure that the processing environment is neat and clean, and reduce the adhesion of impurities such as dust and iron filings. These impurities may scratch the mold surface during processing, causing the surface to be uneven.

Control temperature and humidity: During processing, control the temperature and humidity in the workshop to reduce mold deformation and surface unevenness caused by temperature and humidity changes.

After the non-standard parts are processed, quality inspection is an important step to ensure that the quality of the parts meets the design requirements and usage standards. The following are the main steps and methods for non-standard parts quality inspection:

1. Appearance inspection

Visual inspection: Non-standard parts processing directly observe the surface of the parts with the naked eye to check whether there are obvious defects such as cracks, burrs, bubbles, oxidation, rust, etc. For minor defects, it may be necessary to use a high-magnification microscope for inspection.

Color and gloss: Check whether the color of the part surface is uniform and whether the gloss meets the requirements to judge the quality of the coating or surface treatment.

2. Dimension measurement

Tool selection: According to the design drawings and size requirements of the parts, non-standard parts processing should select appropriate measuring tools, such as rulers, calipers, vernier calipers, micrometers, height gauges, inner diameter gauges, outer diameter gauges, etc.

Precise measurement: Strictly measure according to the dimensions specified in the design drawings to ensure that the key parameters of the parts such as length, diameter, aperture, thickness, etc. meet the tolerance requirements. Measurement errors should be eliminated during the measurement process to ensure the accuracy of the measurement results.

3. Material inspection

Material analysis: According to the design requirements of the parts, the materials of the parts are inspected and analyzed. Commonly used material analysis methods include grinding tests, tensile tests, hardness tests, chemical composition analysis, etc. to determine whether the performance of the materials meets the requirements.

Material certification: Suppliers are required to provide material qualification certificates or quality certificates to ensure that the source and quality of the materials are reliable.

4. Functional testing

Performance evaluation: Non-standard parts processing should carry out corresponding performance tests according to the use environment and functional requirements of the parts. For example, for parts on mechanical equipment, load tests, vibration tests, etc. may be required; for electrical parts, electrical tests and pressure resistance tests, etc. are required.

Simulation test: Use test equipment and processes to simulate the operation process of parts and determine the service life and durability of parts. By simulating the use environment, test the working performance of parts under different conditions to evaluate their actual use effect.

5. Records and reports

Detailed records: During the quality inspection process of non-standard parts processing, the results and data of each inspection should be recorded in detail, including information on appearance inspection, dimensional measurement, material inspection and functional testing.

Quality report: Prepare a detailed quality inspection report based on the recorded data and information. The report should include basic information of the parts, inspection methods, inspection results, existing problems and improvement suggestions.

6. Unqualified processing

Identification and isolation: For parts that fail the inspection, they should be immediately identified and isolated to prevent misuse or mixing with qualified products.

Cause analysis: Analyze the causes of unqualified products to find out the causes and responsible departments that caused the unqualified products.

Improvement measures: According to the results of the cause analysis, non-standard parts processing should formulate corresponding improvement measures and corrective measures to prevent similar problems from happening again.

Want to find the source factory to save money in the middle?

We are the source factory for five-axis non-standard parts customization and various precision and complex parts production and processing, and we have many years of processing experience. Choose us to maximize our interests.

Customized according to your drawing!

Check out our CNC machining quotes. See the quality of our products for yourself and let’s start working together.